Real-time machine health

A plug-and-play SmartMeter that shows critical machine parameters, clear status, and warnings at very low cost.

See what your machine is doing in real time. Green means good. Red means action needed.

Key Benefits

Why Machine Pulse is the right choice for your facility.

Instant Visibility

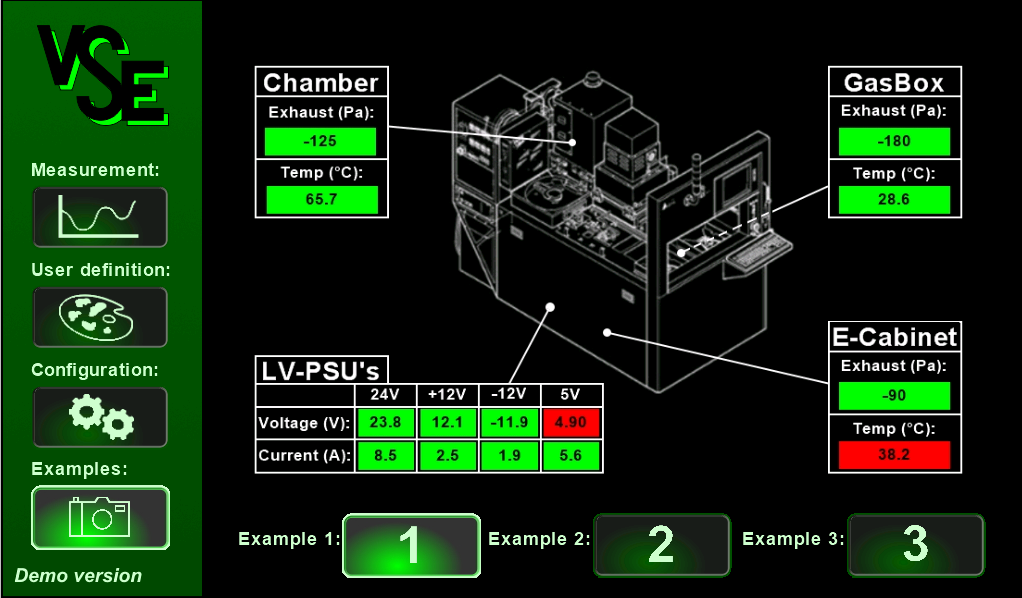

All relevant sensor values displayed clearly on one dashboard. No more guessing games.

Display Machine Status

Integrated LED bar shows status at a glance: Green = OK · Red = Out of limits.

Plug & Play Installation

Voltage-based measurement with all cables and connectors included. No complex integration required.

Early Warnings

Critical parameters are monitored continuously with clear alarms before failures occur.

Machine Protection

Host system can stop the machine automatically via SECS event notification when limits are crossed.

Low-cost Modernization

Upgrade existing machines with modern monitoring - without expensive retrofits.

Scalable Channel Options

Choose the size that fits your machine and monitoring needs.

Compact & Focused

Single sensor monitoring for focused applications. 2.4" compact display.

Standard System

1…8 channel sensor monitoring for basic systems. Clear 7" inch display interface.

Complex Setup

Multi-sensor monitoring (1…16 channels) for complex machine setups. Large 10.1" high-res display.

Technical Features

Engineered for industrial environments and reliability.

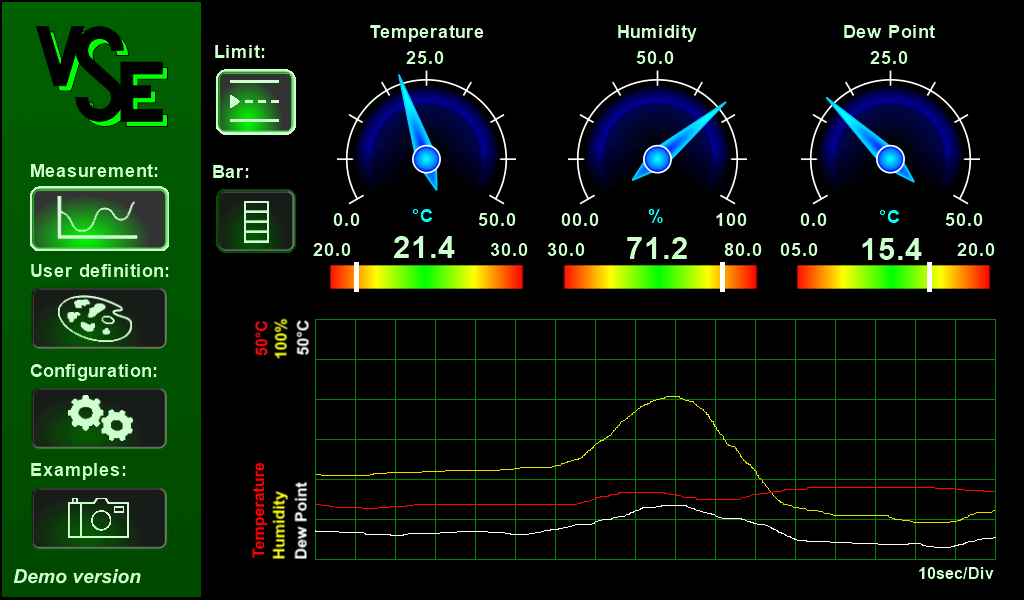

- Real-time data visualization with gauges and graphs

- User-defined limit settings for each channel

- SECS/GEM communication protocol ready

- Comprehensive data logging capabilities

- Complete kit with all necessary cables and connectors

- High-resolution 10.1" display option available

Highly Customizable

Adapt the SmartMeter to your specific monitoring requirements.

- Define sensor channels from 1 up to 16

- UI displays measurements tailored to specific needs

- Light tower settings customizable for visual alerts

- Independent configuration for every channel

How It Benefits You

Direct impact on your operational efficiency and bottom line.

Prevent Downtime

Early warnings help you fix issues before they become expensive failures.

Improve Productivity

Real-time monitoring means you don't waste time troubleshooting blind.

Extend Machine Life

Continuous monitoring helps you maintain optimal performance and catch wear early.

Reduce Costs

Predictive maintenance allows for planned service instead of reactive, costly repairs.

Enhance Quality

Consistent monitoring ensures stable process parameters for better product output.

Simplify Operations

Easy-to-read status indicators mean less training and faster decision-making for operators.

How It Works

Connect

Connect the SmartMeter to your machine using the included cables.

View

Instantly view live sensor data and machine status on the clear display.

Protect

Get warnings or automatically stop the machine when limits are exceeded.

Modernise your machine monitoring

Contact us today to get started

Michael Krähemann