TS CENTERRING – Safest Solution for a Good Sealing of Your Foreline

Using the right sealing products in the subfab exhaust areas has become one of the most critical aspects of the engineering process.

Not only for optimizing the performance when being exposed to high temperature or harsh NF3/O2 environments but also for ensuring safety when it comes to unpredictable gas leakage.

The configuration of a safe and reliable subfab environment is essential and requires careful attention when it comes to the design, as the staff is continuously exposed to toxic or dangerous chemicals.

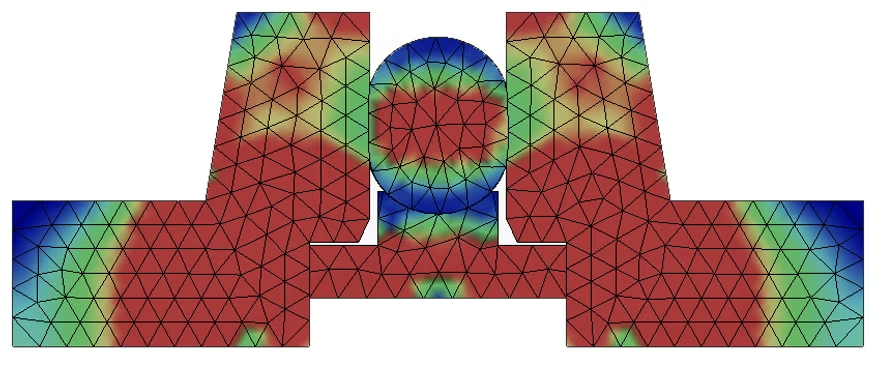

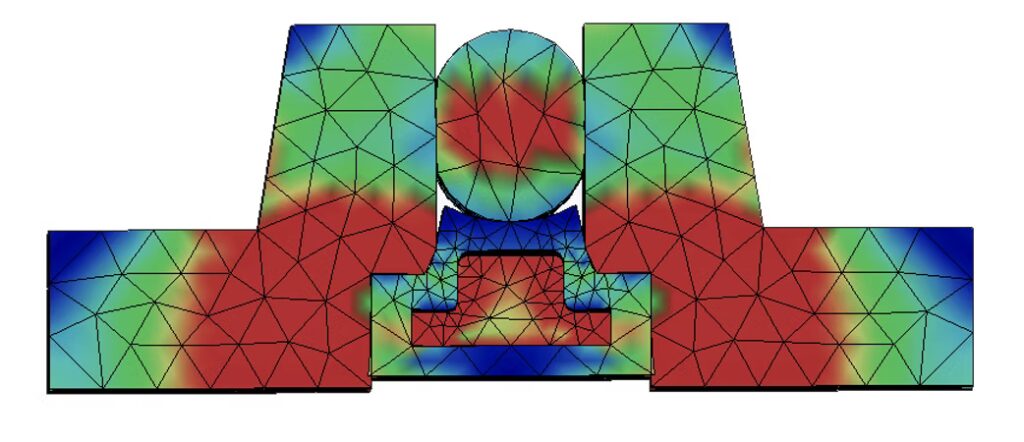

Conventional centering seals are good to join together two flanges and easy to be handled. Nevertheless, with toxic gases always flowing, the escape of flammable compounds can create a fire risk or unnecessary safety risks for the workers.

For this reason, the weak points were carefully studied and as a result, the Triple-Sealing centerrings were developed.

SPM SOLUTION

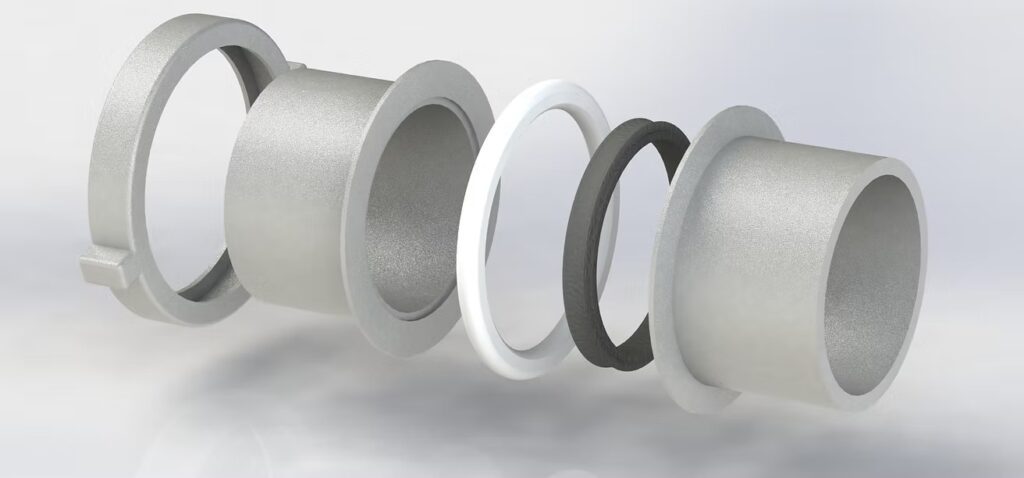

SPM TS-centerring is one of the latest sealing solutions developed for exhaust line. The rubber reinforcement around the inner metal plate and FKM/FFKM outer O-ring improves the resistivity towards harsh NF3 or O2 plasma and high temperatures, being able to withstand up to 325C.

THE BENEFITS

- Safety measurement in order to prevent the leakage of toxic gas: Thanks to the additional sealing point compared to the standard centerring version

- Minimized particle generation: By chemical attack of O2/NF3

- Applicable for standard ISO-KF flanges: KF16–KF200

- Reusable: After O-ring replacement

- Continuous operating temperature up to 325C: Depending on the material

- Powder clogging prevention:On the inner walls

SUCCESS STORIES

One of our customers had old semiconductor tools, where hazardous gasses could leak into surroundings without being noticed. Changing the tools usually means very high costs, therefore switching to TS-Centerrings ensured a safer environment and less worries.

Another one of our customers managed to increase the PM cycle and save time, as he was continuously replacing the centerrings due to aggressive NF3 conditions, causing the premature failure of the part. Not only did lifetime increase, but also the cost of ownership was reduced thanks to the reusability of the TS-Centerring.

Let's comunicate!

Diana Olan via mail: diana@spm.li or via Phone: +423 794 57 91 or

Estera Bujny via mail: estera@spm.li or via Phone: +423 791 79 24.